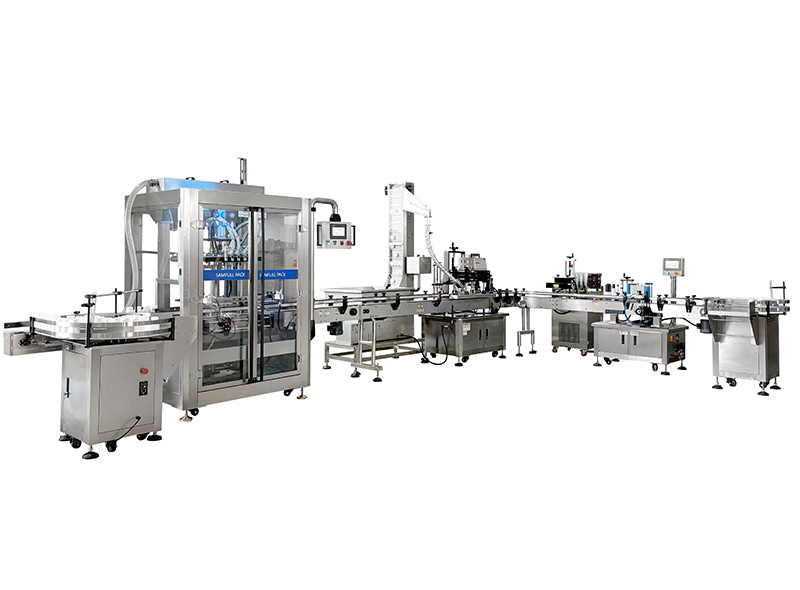

Syrup Bottle Filling Sealing Machine

The liquid automatic bottle filling and sealing machine is suitable for liquid products (such as honey, sauce, paste, chemicals, pharmaceuticals, and cosmetics) filling, sealing(capping), labeling, and so on.

Videos

Features:

Automatic 2 Nozzles Tracking Type Liquid Filling Machine:

Fast machine adjustment: fast switching of bottle type products, with formulasavingfunction. After saving parameters, machine adjustment can be completed withonebutton,which saves time and is very convenient and practical;

Wide range of applicable bottle types: as long as it can stand on the line without fallingand the bottle mouth is vertically upward, it is also applicable to various special-shapedbottles. No special adjustment is required. The bottle can be placed on the conveyor at will,which greatly reduces the labor intensity of workers;

Wide range of applicable products: suitable for cream and oil products in thecosmeticsand food industries: such as: shampoo, laundry detergent, hand soap, shower gel, conditioner, acid oxygen milk, essential oil, food/industrial oil, etc.;

High efficiency: fast filling speed, good stability, filling is controlled by servo motor, andthe filling accuracy is high;

Automatic caps feeding and capping machine:Automatic in-line cover machine is a reference to theinternationaladvanced model improvement design, fast cover speed, highqualifiedrate,convenient operation. Can be applied to food, pharmaceutical, dailychemical,pesticide, cosmetics and other industries of different bottle shapespincover.The machine has a high degree of automation, good stability, convenientadjustment, (such as with the cover machine, can be automaticallycover)canbe selected according to the actual needs.

Water-cooled aluminum foil sealing machine:This equipment is suitable for sealing containers of medicines, foods,cosmetics, pesticides, petroleum products, and chemical products. It usestheprinciple of electromagnetic induction, and the high-frequencysignal isamplified and output by the induction coil. When the container withthealuminum foil inner cover passes through the induction coil, eddy currentsaregenerated and instantaneous heat is generated, so that thealuminumfoilsurface and the bottle mouth are tightly bonded, achieving thepurposeofairtight sealing.