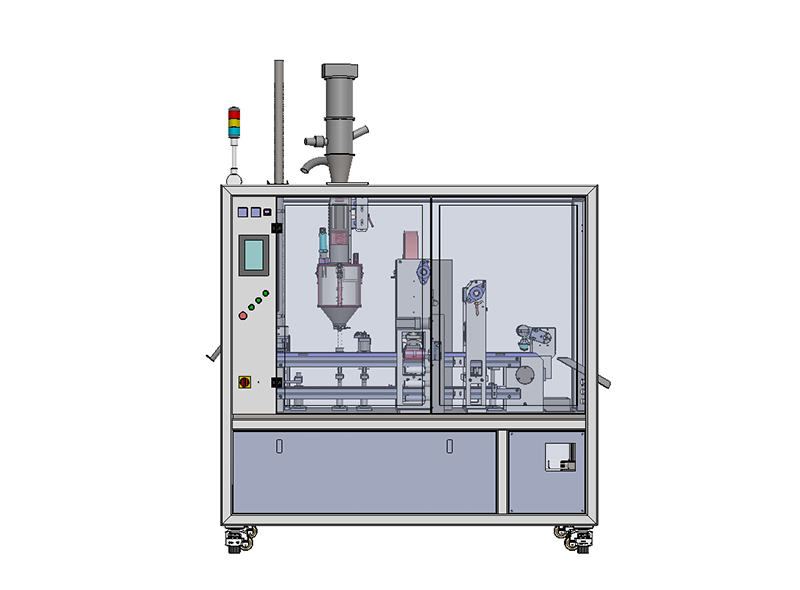

Ground Coffee Capsulee Filling Packing Machine

Application

The capsules produced by our machine can be ensured high quality,high sealing strength,good air tightness and smooth and beautiful appearance.This kind of packing machine has the following characteristics :Stable running, high efficiency, applicable widely, high reliability, high integration degree, high degree of automation, low cost, etc.

Videos

Features

•The machine’s contact with food area is all stainless steel

•High strength and high precision chain wheel, gearbox, bearing and dividing box determine the fast, stable and accurate operation of the machine, long service life and pleasant rhythm.

•The high-quality pneumatic components make the air circuit of the machine run stably, the air pressure inside the machine is stable, and the air flow is even, which greatly avoids the failure, so as to greatly improve the production capacity and guarantee the service life of the machine.

• Electrical parts are from most famous brands with best quality (Schneider, Siemens, Allen-Bradley…)

• Capsule sorter and lifting and conveying system greatly save labor costs;

• UV sterilization system provides a good production environment for capsule production;

•Electromagnetic storm has largely solved the problem of static electricity in the process of powder packaging, resulting in the failure of packaging process;

•The peristaltic pump drop filling device is ready for adding liquid flavors in the capsule in the future;

•The second strengthen heat seal. It eliminates the risk of defective products entering the market, even if the first heat seal fails;

•The online weighing device feeds the data back to the PLC in real time, identifies the defective products and automatically eliminates them;

•Discharging over-turning device prepares for the following packaging of the capsule, bagging or cartoning;

•Automatically counts the output of the finished capsules;

•Roll film cutting and sealing system: with high-precision fine tooth cylinder blade, it can realize online cutting and sealing at the same time, with sealing deviation of 0.1mm. With identification mark system, servo motor drives roll film expansion and dragging, with high precision.

• With nitrogen filling device, it creates a low-pressure environment, when nitrogen source pressure and flow rate meet the conditions, the residual of Oxygen less than2% in the capsule, so that the fresh coffee is sealed and wrapped by highly pure nitrogen;

•The remote control system, to a great extent, solves the problem of international PLC and HMI inconsistency of the software installed on the PC side, and the program update, inspection and backup of the machine can not be solved because of the network problems. Moreover, the customer can observe whether the parameter value of the machine is normal, the failure rate of the machine, the production efficiency and so on in real time every day, which are all through the mobile app can be achieved.

•Screw feeder and vacuum feeder, according to the choice of customers to configure the corresponding automatic replenishment system.