Flour Bag in Box Cartoning Packing Line

Application:

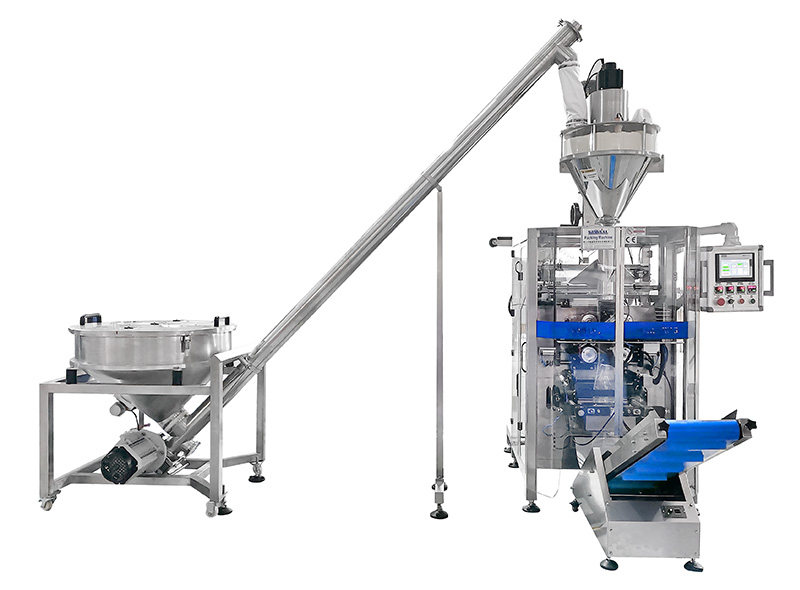

The flour bag and carton packing line is a complete system that integrates multiple machines and processes to efficiently package flour into individual bags, and then group these bags into cartons for easy handling and distribution.

Kindly reminder

Please tell us the following information while you send us an inquiry. Base on your message, we will suggest the optimum solution to you for reference. Thank you.

1. Bag dimension

2. Bag weight

3. Your product

4. Bag shape

5. Bag material

Videos of VFFS powder bag making connect with box packing:

The components and steps involved in a flour bag and carton packing line can vary based on the specific needs and scale of the operation. However, here are the typical stages you might find in such a packing line:

1. Flour Feeding: The process begins with the flour being transported from storage silos to the packing line. This may involve conveying systems that move the flour to the filling area.

2. Bag Forming and Filling: Empty bags are formed from a roll of film, and they are then filled with the appropriate amount of flour. The bags can be made of various materials, such as paper, plastic, or a combination of both.

3. Bag Sealing: Once filled, the bags are sealed to prevent any spillage or contamination during transportation.

4. Bag Coding and Printing: Optional equipment in the line can be used to print batch numbers, expiration dates, or other relevant information on the bags for traceability.

5. Bag Checkweighing and Metal Detection (optional): Some lines may include checkweighers to ensure that each bag has the correct weight of flour. Metal detectors are also used to identify and remove any metal contaminants from the bags.

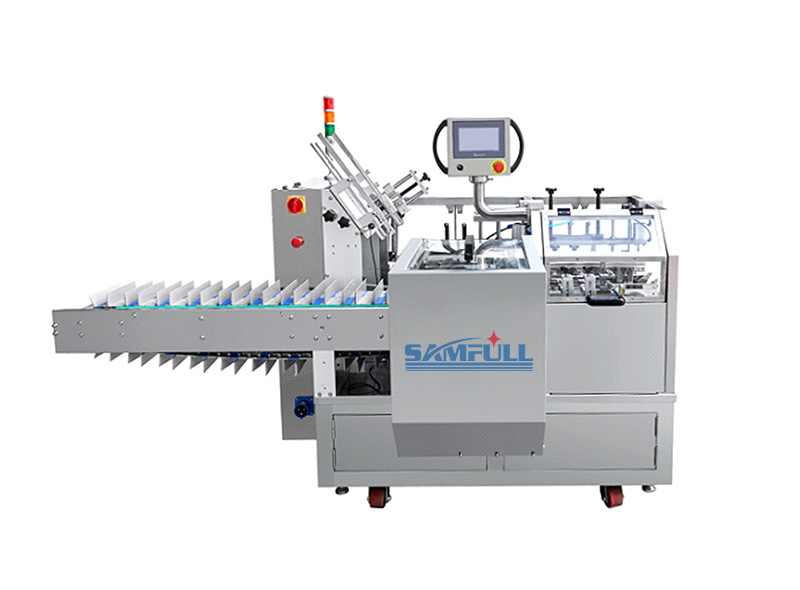

6. Bag Cartoning: Filled and sealed bags are then grouped into cartons or boxes. The cartons are pre-formed and supplied to the packing line. The bags are automatically inserted into the cartons.

7. Carton Sealing: The cartons are sealed using adhesives, tapes, or other methods to secure the bags inside.

8. Carton Labeling: Optional labeling equipment can apply product information, barcodes, and other labels to the cartons for proper identification.