Powder Pre-made Pouch Doypack Filling Sealing Machine

Application

The Powder Pre-made Pouch Doypack Filling Sealing Machine is a specialized packaging equipment designed to automate the process of filling and sealing pre-formed pouch or doypack pouches containing powdered products.

Kindly reminder

Please tell us the following information while you send us an inquiry. Base on your message, we will suggest the optimum solution to you for reference. Thank you.

1. Your product

2. Bag dimension

3. Bag weight

4. Bag shape

5. Output capacity

Videos

Powder premade pouch doypack samples

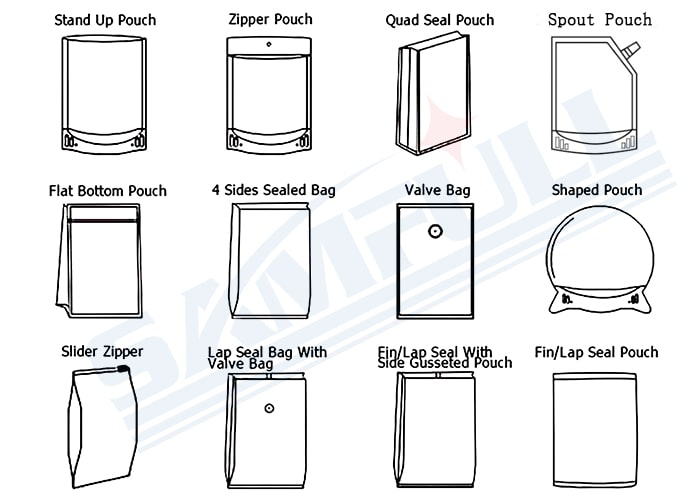

Bag Shape Options

1. Doypack pouch

2. Resealable zipper pouch

3. Quad seal stand up pouch

4. Spouted pouch

5. Pouch with hanging hole

6. Other customized premade pouch

Features

1. Stainless steel appearance, beautiful and high-grade, stable operation;

2. Replace manual packaging, the production efficiency is increased, and the production cost is greatly reduced;

3. Adopt PLC control, touch screen operation, a wide range of use, set the speed of operation according to production capacity requirements;

4. Changing the size of the bags quickly and easily which can be adjusted by handle;

5. Automatic detection function, the pouch can be recycle used if these situation happens: bags can not open or open the bag incomplete, no feeding, no heat sealing;

6. It can be used in doypack bags, handbags, zipper bags, four-sided bags, three-sided bags, paper bags, M-shaped bags and other composite bags;

7. It can automatically perform the functions of suction bag, date printing, bag opening, materials filling, bag sealing, finished product output.

Working Process

1. Pouch Loading: Pre-formed doypack pouches are manually loaded onto the machine's feeding system or conveyor. These pouches are already formed with a bottom gusset that allows them to stand upright.

2. Pouch Opening: The machine opens each pouch, ensuring it is ready to be filled with the powdered product. This is often achieved using mechanical grippers or suction cups.

3. Product Dispensing: The powdered product is fed into the machine's dosing system or hopper. Depending on the specific product characteristics, a volumetric filler, auger filler, or another dosing mechanism is used to accurately dispense the desired amount of powder into each pouch.

4. Filling: The powdered product is carefully deposited into each doypack pouch. The machine ensures accurate and consistent filling to maintain product weight and quality.

5. Sealing: Once the pouches are filled, the machine proceeds to the sealing stage. This involves sealing the open top of each pouch using heat-sealing technology. The heat-sealing process ensures a secure and airtight seal to preserve product freshness.

6. Optional Steps: Depending on the specific machine's capabilities and the product's requirements, additional steps might be included:

Printing date codes, batch numbers, or other information on each pouch for traceability.

Applying tear notches to facilitate easy opening of the pouches.

Incorporating zipper closures or spouts for resealable doypack pouches.

Nitrogen Gas filling for milk powder or other products are required.

Dust remove device for pouch sealing part.